OUR SERVICES

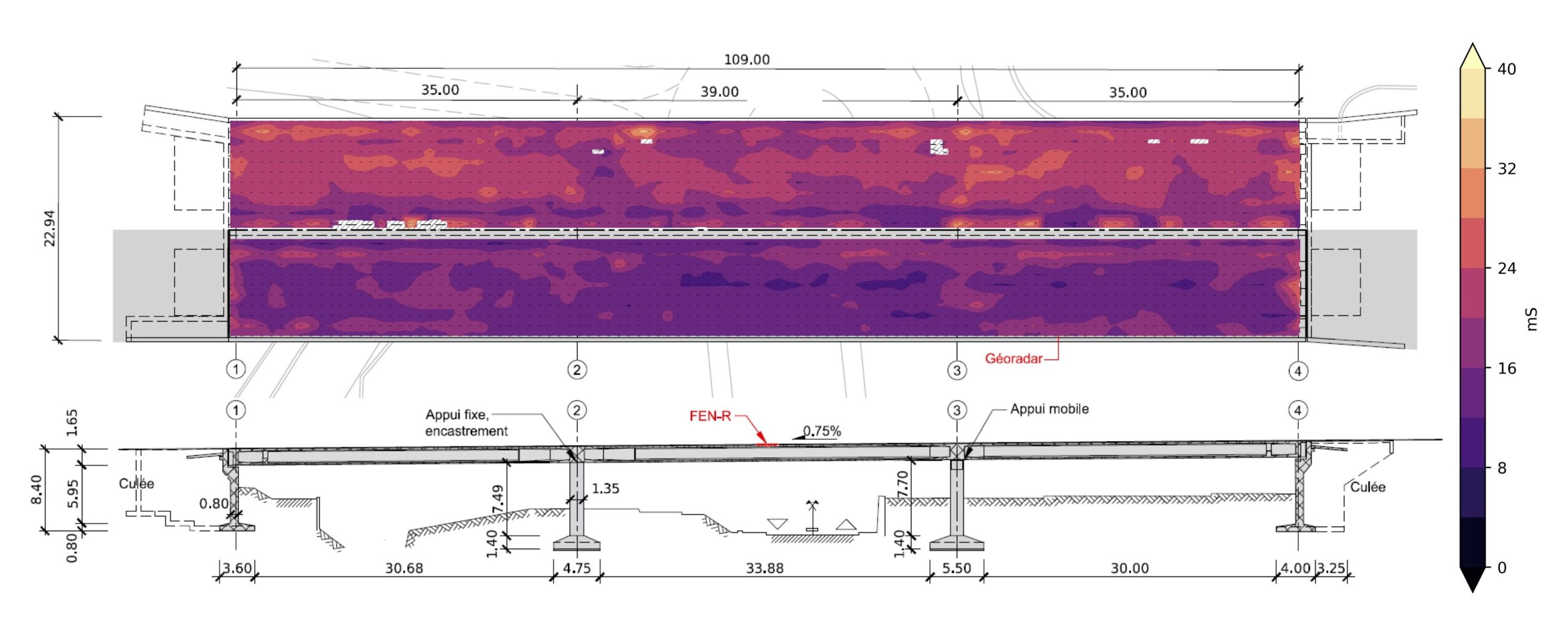

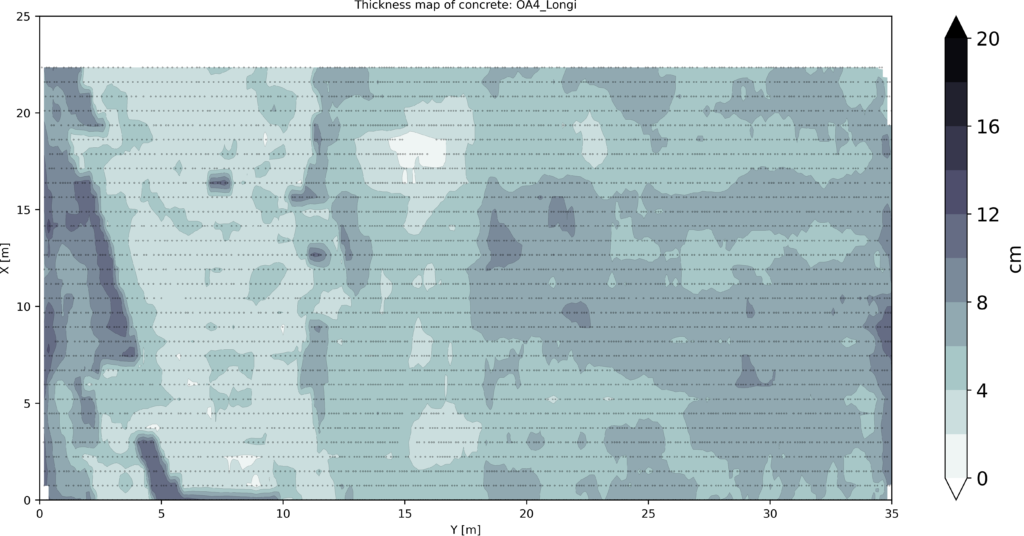

Our services can be separated into two important parts, namely, field measurement service and in-house analysis service. By Field service, our engineering team comes with a Ground Penetrating Radar device to measure the structure. The length of the service depends very much on the size of the structure. By In-house service, we process the acquired data from the clients and provide our studies in the form of graphically summarised maps and reports.

Contamination and corrosion risk

With the help of our studies, our customers can evaluate the risk of corrosion of the reinforcement and take early action to prevent, slowdown or even stop the corrosion process. Thanks to our data, the repairs can be localized and applied only to the required areas.

BRIDGOLOGY

Le Grand-Chemin 73

Epalinges, CH-1066

T +41 79 297 40 54

info@bridgology.com

©Bridgology 2023

Designed by Swiss Backstage

Designed by Swiss Backstage | ©Bridgology 2024